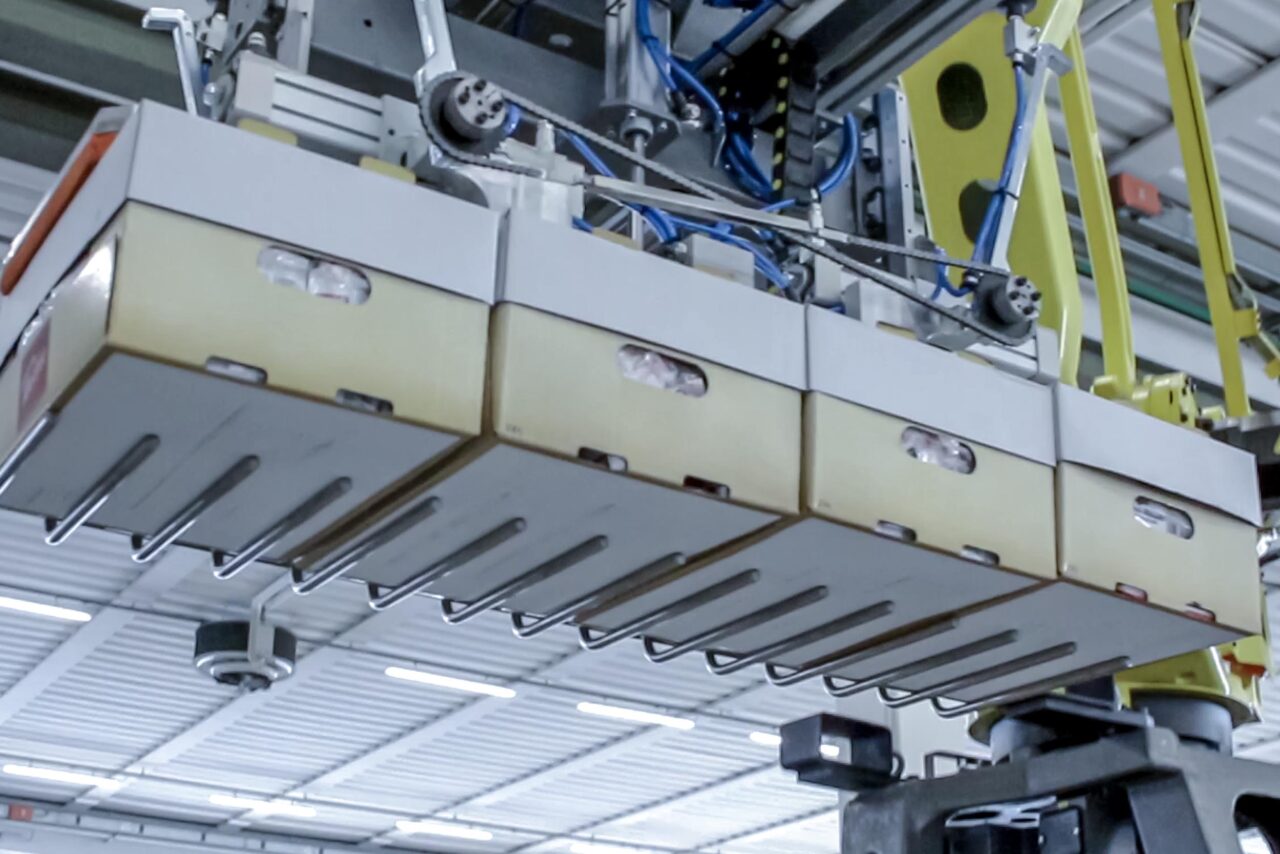

This system is composed of 1 machine and some other devices, all designed, produced and tested in our main plant.

Customer’s requirement is to have an end-of-line system linked with his pre-existent automation; more specifically, it will manage coffee packs (production range from 20 to 30 bags per minute) and prepare cartons with packs in the required size (from 100 to 225 boxes per hour).

In the first place there is a motorized belt carrying and placing the packs coming from the packaging machine; packs can come in 3 different sizes: 250, 500 and 1000 g. The casepacking compact system forms the american carton, puts the packs inside in 3 different sizes (6×3, 5×2, 4×2, in vertical position) and in the end it gets closed by a taping head. A second belt carries closed cartons towards the employee who brings them to the warehouse.

- Adaptability ( 3 pack sizes, 3 carton sizes)

- Preformation Buffer (High production management)

- Versatility (Complete integration with the pre-existent packaging system)