The project consists in a complete case packing system, includes 4 machines and some other devices all designed, produced and tested in our main plant.

The customer’s requirement is to manage an automatic production of PET bottles containing vegetable oil (4 different types in variable capacity); containers coming out from the existing filler (a production between 10.000 and 17.000 bottles per hour), are conveyed to the case packer (a production between 1433 and 1785 cartons per hour), packed, automatically closed and arranged by the operator.

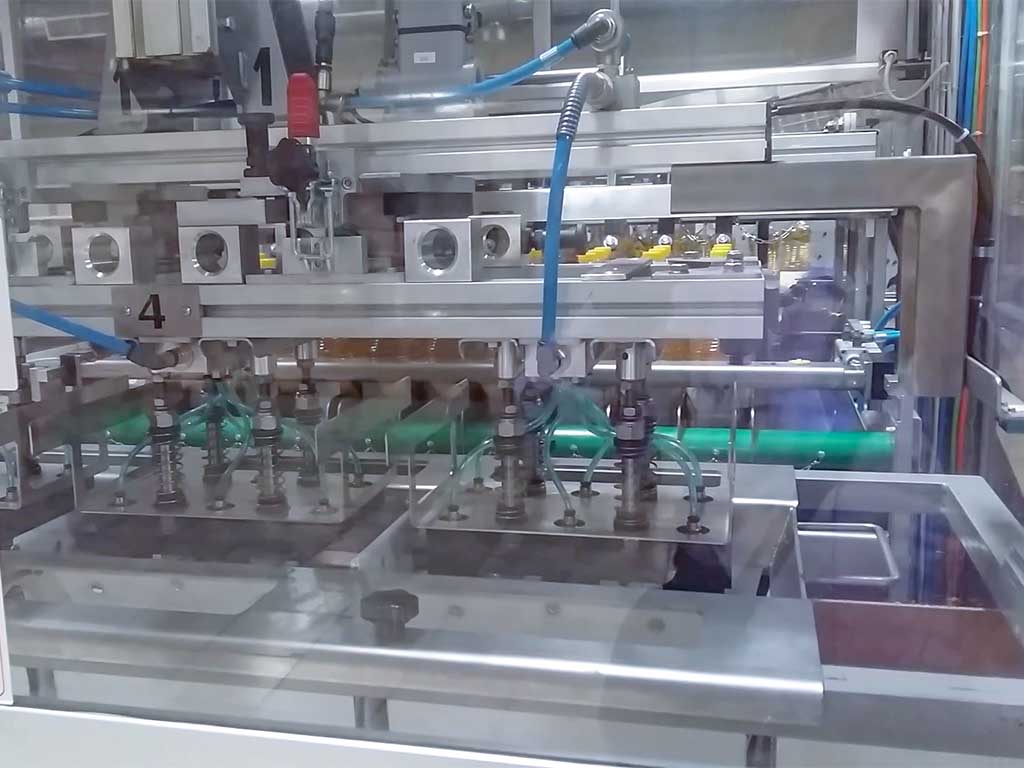

The complete line is made of a carton forming machine, a machine arranging bottles following the required schemes and inserting them in the American carton, a weight checker and a carton closer.

The supply also includes some other devices: cartons transportation roller units, cadencing belt, changing heads cart and warehouse, protections and accident prevention devices.

- Safety (Protections all over the system perimeter)

- Automation (Centralized lubrication)

- Customization (applied containers for collecting liquids in case of bottles break)