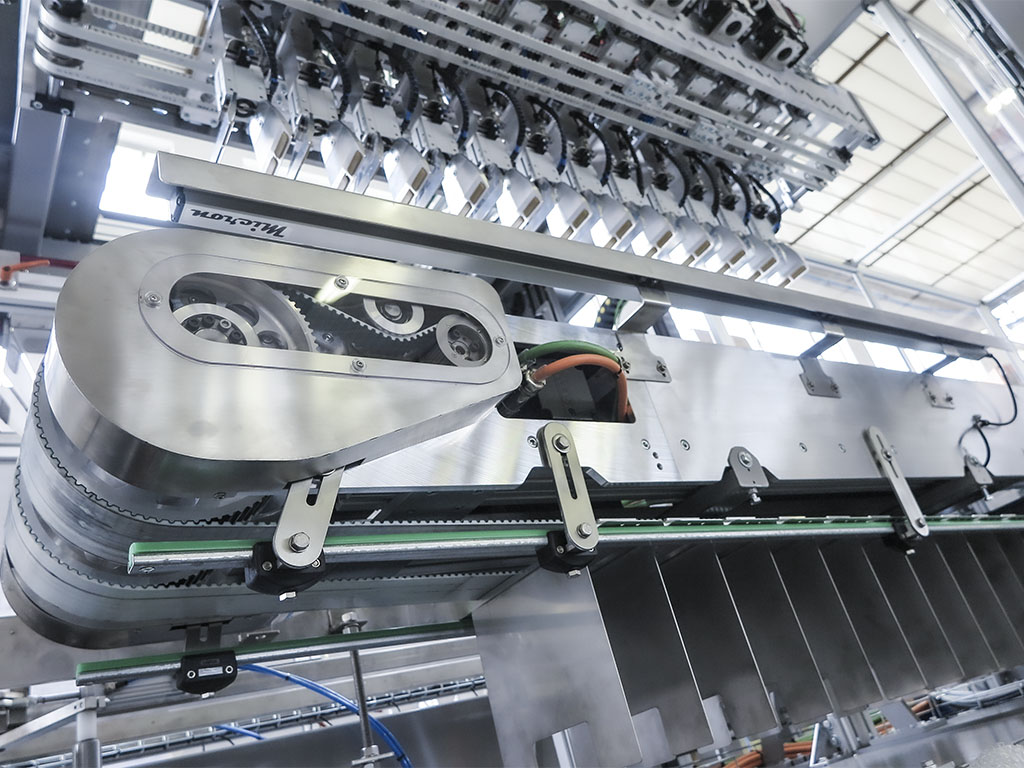

This system is composed of one machine and some other devices, all designed, produced and tested in our main plant.

Customer’s requirement is to have an end-of-line system linked with his pre-existent automation; more specifically, it will manage different sizes of DOYPACK containing homecare detergent, carried and arranged into american cartons.

There is only one size of product but this machine is designed for managing different sizes through special adjustable elements; for this 1,8 liters size, the present production gets 1800 doypack per hour and it will get to 3600 pieces per hour.

The self-adjustable picking head allows to prepare different sizes of carton depending on the customer’s production needs.

- Safety (Protections all over the system perimeter and size changing devices)

- Versatility (Total integration with the pre-existent packaging system)

- Adaptability (Loader and picking head adjustable over product’s size and production)