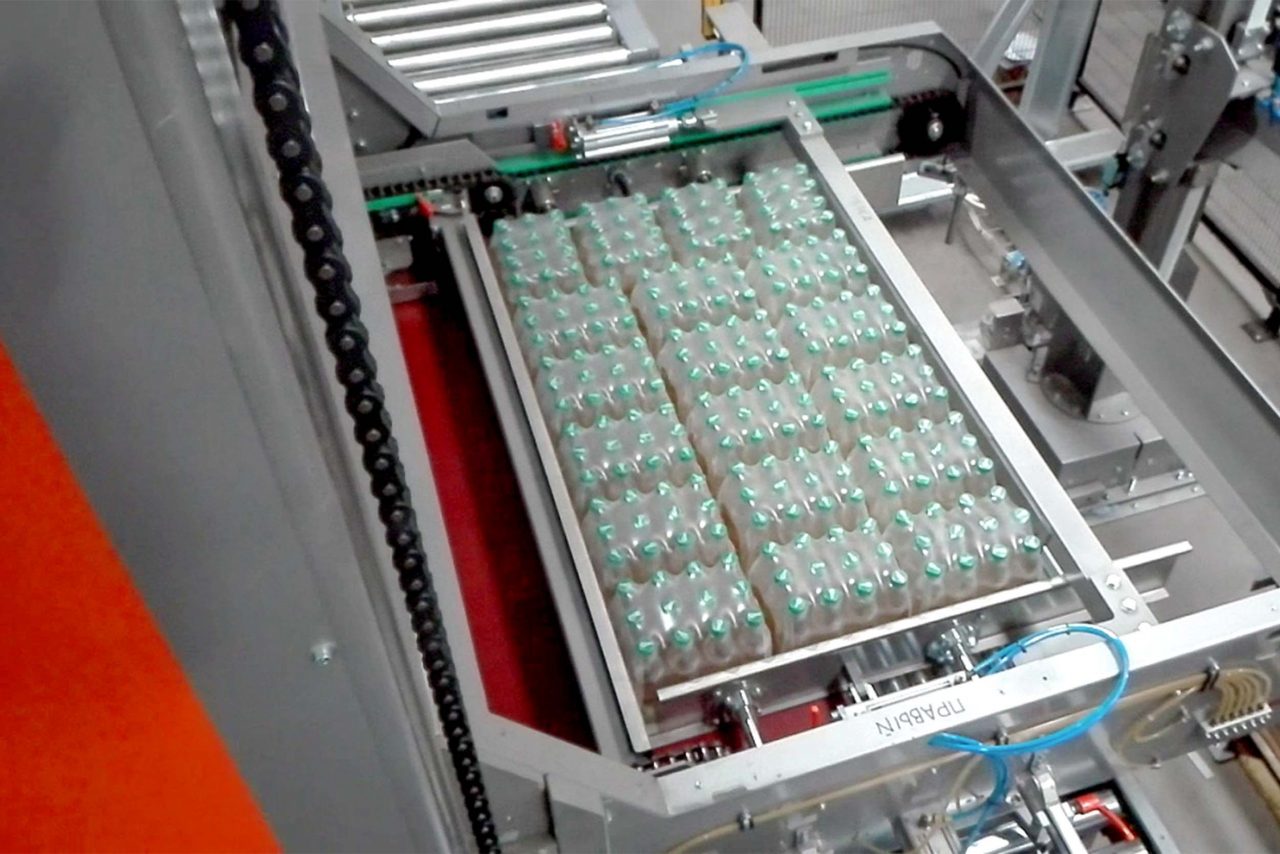

This project is focused on the palletizing phase of an automatic system handling bundled PET bottles containing mineral water, all designed, produced and tested in our main plant.

The customer’s requirement is to manage a production of 38.400 bottles per hour, there are two formats of bottle, 1,5 l and 0,5 l, while pallets are made of wood in two sizes (1200 x 800 h.140 mm and 800 x 600 h.140 mm).

The supply includes the transportation system moving the bundles towards the robot, a number of belts arranging the lots on an accumulation point, following the scheme required by the pallet’s layer. The bucket picking head takes the entire layer and arranges it on the palletizing area.

The supply also includes some other devices: pallet storage and middle-layers, full and empty pallet transportation rollers, protective film applying ring winder, safety and protection systems.

- Safety (Protections all over the system perimeter)

- Versatility (Different formats of product and types of pallet management)

- Reliability (total management of the end-of-line system)